-

Top 10 Workplace Safety Tips Every Employee Should Know

Workplace safety is a paramount concern for both employees and employers. Ensuring a safe work environment not only protects the well-being of workers but also contributes to increased productivity and reduced downtime due to accidents. As an employee, it is crucial to be proactive in safeguarding your own safety and that of your colleagues. This article presents the top 10 workplace safety tips that every employee should know and follow diligently.

Tip 1: Familiarize Yourself with Emergency Procedures

Emergency situations can arise unexpectedly, and being prepared is crucial. Take the time to familiarize yourself with emergency exits, evacuation routes, and assembly points. Knowing the location and proper usage of fire extinguishers and first-aid kits can make a significant difference during critical moments. Regularly participate in emergency drills to reinforce your knowledge and responsiveness.

Tip 2: Practice Proper Lifting Techniques

Many workplace injuries stem from improper lifting of heavy objects. To protect your back and reduce strain, use proper lifting techniques. Bend your knees, keep your back straight, and lift with your legs, not your back. If an object is too heavy or awkward to lift, seek help from a colleague or use lifting aids whenever possible.

Tip 3: Keep Work Areas Clean and Organized

A cluttered and messy workspace poses numerous hazards. Keep your work area clean and well-organized to minimize tripping hazards and prevent accidents. Always return tools and equipment to their designated storage spaces after use. Properly store chemicals and hazardous materials in their appropriate containers and label them accordingly.

Tip 4: Utilize Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) plays a vital role in safeguarding employees from various workplace hazards. Depending on the job and its associated risks, PPE may include safety goggles, gloves, hard hats, earplugs, and more. Ensure that you wear the right PPE for the task at hand and that it fits properly. Regularly inspect and maintain your PPE to ensure its effectiveness.

Tip 5: Be Mindful of Ergonomics

Ergonomics is the study of designing and arranging workspaces to maximize efficiency and reduce the risk of injuries. Poor ergonomics can lead to musculoskeletal disorders and chronic pain. Adjust your workstation to maintain proper posture and reduce strain on your body. Use ergonomic chairs, keyboard trays, and monitor stands to create a comfortable and safe workspace.

We spoke with Wendell, who works for one of the highest rated fence companies in Tyler Texas, and he told us that, in addition to ergonomic hammers, he make sure his employees get regular breaks. The nature of a fencing business involves a lot of work on ladders and a lot of work down low. By taking proper breaks, Wendell believes his fencing contractors see less injuries and perform better.

Tip 6: Avoid Distractions and Stay Focused

Distractions in the workplace can be dangerous, especially in high-risk areas. Always remain focused on the task at hand and avoid engaging in activities that could divert your attention. Refrain from using personal devices or taking unnecessary breaks when operating machinery or working in hazardous environments.

Tip 7: Report Potential Hazards Immediately

If you notice any safety hazards or potential risks in the workplace, report them immediately to your supervisor or safety personnel. Open communication about safety concerns is essential to prevent accidents and address issues promptly. Taking early action can prevent minor hazards from escalating into serious incidents.

Tip 8: Take Regular Breaks and Manage Fatigue

Fatigue can impair judgment and reaction times, leading to an increased risk of accidents. Take regular breaks throughout the workday and ensure you get enough rest outside of work. Proper time management and maintaining a healthy work-life balance can help reduce fatigue and improve overall safety.

Tip 9: Follow Lockout/Tagout Procedures

Lockout/Tagout procedures are critical for preventing accidents when working with energized equipment or machinery. Always comply with these protocols when conducting maintenance or repairs on machinery. Following proper lockout/tagout procedures ensures that equipment is safely shut down and unable to start unexpectedly, protecting you and your colleagues from potential harm.

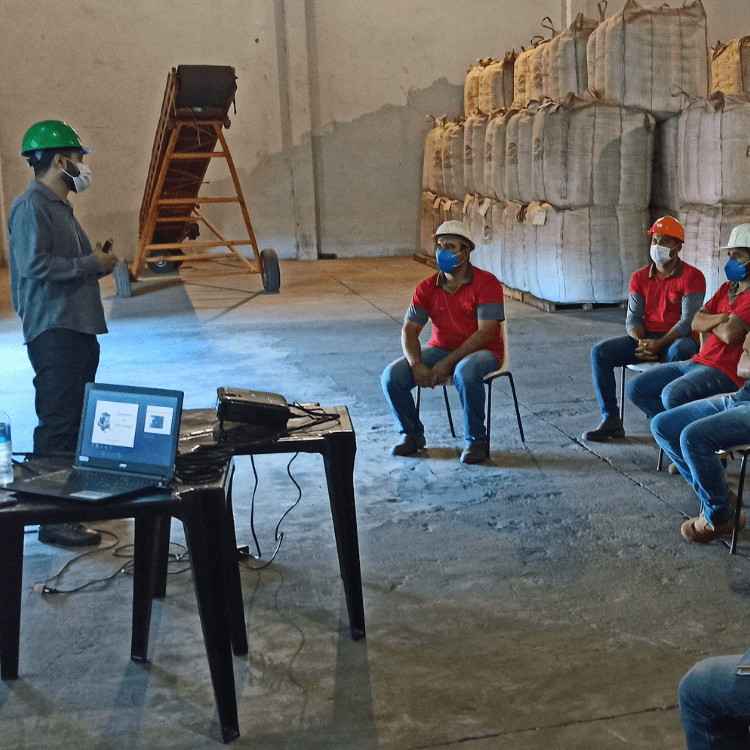

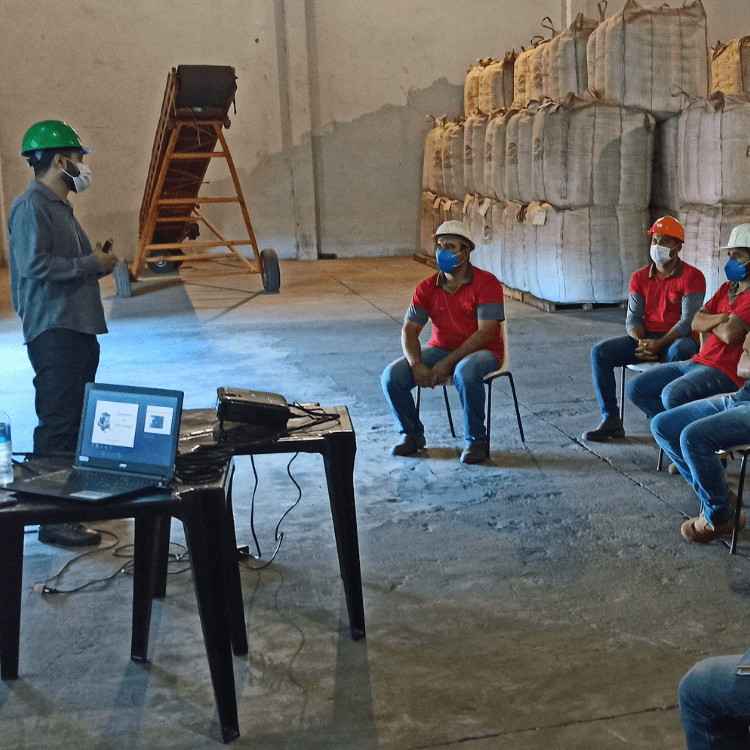

Tip 10: Participate in Safety Training and Programs

Safety training is an ongoing process that equips employees with essential knowledge and skills to identify and mitigate workplace hazards. Attend all safety training sessions provided by your employer and actively engage in safety programs. Be proactive in suggesting safety improvements and participate in safety committees or initiatives to promote a safety-conscious culture within the workplace.

Conclusion

Prioritizing workplace safety is a shared responsibility that every employee must uphold. By adhering to these top 10 workplace safety tips, you contribute to creating a safer work environment for yourself and your colleagues. Take ownership of your safety, stay vigilant, and collaborate with your employer to foster a workplace culture that values and prioritizes the well-being of everyone. Together, we can build a safer and more productive workplace for all.

-

Marine Construction: Safety Issues and Improvements

Marine construction, a sector dedicated to projects ranging from shipbuilding to the creation of offshore structures and coastal defenses, has a unique set of safety challenges due to its inherently hazardous working conditions. However, over the years, there have been significant strides made in improving safety and reducing the number of accidents in this sector. This article explores both the safety issues still present in marine construction and the advancements that have led to improvements.

Safety Issues in Marine Construction

1. Harsh and Variable Working Conditions

Marine construction workers often face harsh environmental conditions such as high winds, turbulent waters, and unpredictable weather, which can contribute to a higher risk of accidents. These conditions can lead to slips and falls, structural collapses, and maritime incidents like ship collisions.

2. Diving-Related Risks

Underwater construction, maintenance, and repair form a significant part of marine construction. Diving activities carry inherent risks such as decompression sickness, hypothermia, and potential entrapment in underwater structures. Companies that build docks, like Hollywood Marine Construction, are particularly susceptible to these types of accidents and injuries. Although many peers can be pneumatically or hydraulically rammed into submerged surfaces, there are still some instances where these types of installations require divers under the water to either guide the machinery, or do the work manually by hand. These types of installations come with increased risks.

3. Heavy Equipment and Machinery

The use of heavy machinery and equipment, common in marine construction, also presents significant safety risks. Workers can be injured in equipment malfunctions or accidents, and improperly secured equipment can fall into water, creating a dangerous situation.

4. Chemical and Biological Hazards

Workers in marine construction may be exposed to various chemical and biological hazards. Exposure to harmful substances used in the construction process or encountered in the marine environment can lead to serious health issues.

Safety Improvements in Marine Construction

Despite these challenges, there have been several improvements in the safety of marine construction, driven by technological advancements, regulatory efforts, and a growing emphasis on safety culture.

1. Enhanced Safety Regulations

Marine construction projects are now subject to stringent safety regulations. Regulatory bodies like the Occupational Safety and Health Administration (OSHA) in the U.S. and the Health and Safety Executive (HSE) in the U.K. have enforced safety standards that govern various aspects of marine construction, from the use of protective equipment to the handling of hazardous materials.

2. Advancements in Safety Equipment

Technological innovations have resulted in more effective safety equipment, which plays a crucial role in reducing accidents. Modern personal flotation devices (PFDs), for example, are not only more comfortable but also offer better buoyancy and visibility. Enhanced dive suits and breathing apparatus have significantly increased safety for divers.

3. Training and Education

There’s been a significant emphasis on safety training and education. Workers are now routinely trained in risk assessment, emergency procedures, and safe equipment operation. Additionally, many companies have implemented training programs focusing on the physical and mental health of their workers, acknowledging that a healthy worker is less likely to be involved in an accident.

4. Development of a Safety Culture

Many marine construction companies have worked to foster a culture that prioritizes safety. This approach goes beyond merely complying with regulations and seeks to integrate safety into every aspect of the work, from planning to execution. A strong safety culture encourages workers to look out for one another, report potential hazards, and take proactive steps to prevent accidents.

In conclusion, while safety challenges persist in marine construction due to the nature of the work, there have been substantial improvements in recent years. The emphasis on safety regulations, technological advancements, effective training programs, and the development of a safety culture are all driving the industry towards a safer future. Continuous attention to these factors is crucial for maintaining this positive trajectory.

-

Ensuring a Secure Workplace

Safety is essential in any workplace, but in the case of workplaces, there are more risks. Whether you’re an experienced professional or a newbie to the field, learning and using the most effective procedures for workplace safety is essential to safeguarding the safety of your employees, yourself, and your company. This guide’s comprehensiveness is intended to give you the essential skills and strategies to ensure a safe working area, recognize potential risks, and develop safe procedures. Let’s begin this journey as a team, and ensure that everyone is safely home when we finish the day.

Why Jobsite Safety Matters

Safety on the job site can’t be understated. Each year, thousands of incidents occur at work sites that result in deaths, injuries, and substantial financial losses to businesses. Safe working conditions do more than safeguard the health of employees; they increase productivity as well as reduce interruptions because of incidents. Furthermore, following the safety rules and guidelines will protect your business against legal liability.

1. Conducting a Comprehensive Safety Assessment

The first step in ensuring jobsite safety is conducting a thorough safety assessment. Start by identifying potential hazards and risks unique to your specific worksite. Engage with your team to gain valuable insights and perspectives, as they are on the front lines and may have a better understanding of potential dangers.

During the assessment, consider factors such as:

- Physical Hazards: Identify any hazards related to equipment, machinery, or the overall layout of the worksite.

- Chemical Hazards: Ensure proper storage and handling of hazardous materials to prevent accidents.

- Environmental Factors: Consider weather conditions and their impact on safety.

- Ergonomic Concerns: Assess repetitive tasks and ensure proper ergonomics to prevent musculoskeletal issues.

2. Implementing Safety Measures

Once you’ve identified potential hazards, it’s time to implement safety measures to mitigate risks. Create a comprehensive safety plan that includes:

- Personal Protective Equipment (PPE): Mandate the use of appropriate PPE, such as hard hats, safety goggles, gloves, and ear protection, based on the specific job requirements.

- Safety Training: Conduct regular safety training sessions to educate employees about potential hazards and the correct use of safety equipment.

- Safety Signage: Clearly mark hazardous areas and provide safety signs to alert workers about potential risks.

- Emergency Response Plan: Develop and practice an emergency response plan to handle accidents and evacuate the worksite if necessary.

3. Maintaining Equipment and Machinery

Regular maintenance of equipment and machinery is crucial for preventing accidents. Inspect and service all tools and machinery periodically to ensure they are in optimal working condition. Faulty equipment can lead to dangerous incidents, so make sure to address any issues promptly.

4. Promote a Safety Culture

Fostering a safety-first culture among your workforce is key to maintaining a secure jobsite. Encourage employees to report safety concerns and near-miss incidents without fear of reprisal. Recognize and reward those who actively contribute to a safe working environment.

5. Regular Safety Audits

Periodic safety audits are essential to assess the effectiveness of your safety measures and identify areas for improvement. Engage an external safety consultant to conduct thorough audits and provide unbiased insights into your safety practices.

6. Compliance with Safety Regulations

Stay updated with local and national safety regulations relevant to your industry. Compliance with these regulations is not only a legal obligation but also a way to ensure the well-being of your employees and avoid costly penalties.

7. Regular Safety Meetings

Conduct regular safety meetings with your workforce to discuss safety-related topics, address concerns, and reinforce safety protocols. Keep the lines of communication open, allowing employees to share their experiences and suggestions for improvement.

Conclusion

In conclusion, prioritizing jobsite safety is a non-negotiable aspect of running a successful business. By following the comprehensive guide we’ve provided, you can create a safer working environment for your employees, reduce accidents, and improve overall productivity.

Remember, safety is an ongoing process, and continuous improvement is essential. Embrace a safety-first mindset, and together, we can make your jobsite a secure and thriving workplace.

-

Fostering Employee Responsibility in Safety Practices

Safety in the workplace is paramount for any organization. With potential hazards and accidents lurking around every corner, it becomes crucial to foster a culture of responsibility among employees. The human factor plays a vital role in ensuring workplace safety, as it is the collective actions of individuals that can make a significant difference. In this article, we will delve into the importance of employee responsibility in safety practices and explore practical strategies to promote a safer working environment.

The Significance of Employee Responsibility

- Understanding the Impact of Employee Behavior

Employees’ actions and decisions directly influence workplace safety. A single act of negligence or carelessness can lead to severe accidents, affecting not only the individual but also their colleagues and the overall productivity of the organization. It is essential to comprehend the ripple effect of employee behavior on safety practices.

- Building a Safety Culture

A strong safety culture can be established when employees are actively engaged in promoting safety protocols. It involves cultivating a mindset where every worker considers safety as a personal responsibility and actively looks out for potential hazards or risks.

Strategies to Foster Employee Responsibility in Safety Practices

- Comprehensive Training Programs

Implementing well-structured and ongoing safety training programs is crucial. These programs should cover various aspects of workplace safety, including hazard identification, proper use of safety equipment, emergency procedures, and best practices. Regular training sessions help reinforce safety protocols and empower employees to take responsibility for their own safety and that of others.

- Leading by Example

Organizational leaders play a pivotal role in influencing employee behavior. When leaders prioritize safety and actively demonstrate safe practices, it creates a domino effect on the rest of the workforce. Employees are more likely to adopt responsible safety behaviors when they see their supervisors and managers following the same protocols.

- Encouraging Open Communication

Creating an environment where employees feel comfortable expressing safety concerns or reporting potential hazards is vital. Regular safety meetings and open-door policies can foster open communication channels, enabling prompt action on safety-related matters.

- Recognizing and Rewarding Safe Behavior

Incentivizing safe behavior encourages employees to take ownership of safety practices. Organizations can introduce safety reward programs where individuals or teams adhering to safety protocols are recognized and rewarded for their contributions.

Promoting employee responsibility in safety practices is a collaborative effort that requires active participation from all levels of an organization. By instilling a culture of safety and accountability, businesses can minimize workplace accidents and create a safer, more productive work environment. Remember, safety is everyone’s responsibility.

FAQs

1. Why is employee responsibility important for workplace safety?

Employee responsibility is crucial for workplace safety because the actions of individuals directly impact the overall safety culture of the organization. Responsible behavior reduces the likelihood of accidents and promotes a safer work environment.

2. How can organizations foster a culture of responsibility?

Organizations can foster a culture of responsibility by providing comprehensive safety training, leading by example, encouraging open communication, and recognizing and rewarding safe behavior.

3. What role do leaders play in promoting safety?

Leaders play a significant role in promoting safety by setting an example and prioritizing safety in their actions and decisions. Their commitment to safety influences employees to follow suit.

4. How can employees contribute to safety improvement?

Employees can contribute to safety improvement by being vigilant, reporting potential hazards, and actively participating in safety training and initiatives.

5. What are the benefits of a strong safety culture?

A strong safety culture leads to reduced accidents, improved employee morale, increased productivity, and enhanced reputation for the organization.

-

High-Risk Professions

A Closer Look at the World’s Most Dangerous Jobs

In the pursuit of progress and development, numerous industries demand individuals to take on high-risk professions. These jobs require unwavering dedication, immense skill, and, most importantly, the willingness to put one’s life on the line. In this article, we delve into some of the world’s most dangerous jobs, exploring the challenges, risks, and the people who bravely embrace these occupations.

Understanding High-Risk Professions

Defining High-Risk Professions

High-risk professions are occupations that expose workers to significant dangers and hazards regularly. These jobs often involve working in extreme conditions, dealing with life-threatening situations, and facing potential injuries or fatalities.

Factors Contributing to High Risk

Several factors contribute to the high-risk nature of these professions. Some of the common elements include exposure to hazardous materials, extreme environments, physically demanding tasks, high-stress situations, and the unpredictability of certain industries.

The World’s Most Dangerous Jobs

- Firefighters

Firefighters are true heroes who battle raging infernos to protect lives and property. They face immense risks, including collapsing structures, smoke inhalation, and explosions. Firefighting demands extensive training and a deep sense of responsibility.

- Loggers

Working in dense forests, loggers deal with heavy machinery and falling trees daily. The potential for accidents is ever-present, making logging one of the riskiest professions, especially in remote and challenging terrains.

- Fishermen

Fishermen brave the open seas to catch seafood, enduring rough weather conditions and unpredictable waters. They often face dangers from storms, capsizing boats, and working with heavy equipment.

- Construction Workers

Construction sites are full of hazards, from falls and collapsing structures to the operation of heavy machinery. Construction workers need to be vigilant and follow strict safety protocols to mitigate risks.

- Miners

Mining involves digging deep into the earth to extract valuable minerals. Miners face the threat of cave-ins, toxic gases, and equipment malfunctions, making it an extremely dangerous profession.

- Police Officers

Police officers put themselves in harm’s way to uphold law and order. They encounter dangerous criminals, face potential gunfire, and must make split-second decisions that impact lives.

- Aircraft Pilots

Pilots navigate through the skies, dealing with unpredictable weather, technical malfunctions, and the responsibility of hundreds of lives on board.

- Roofers

Roofers work at great heights, exposed to the risk of falls and accidents while handling tools and materials.

- Power Line Technicians

Power line technicians repair and maintain electrical lines, often working at dangerous heights and in adverse weather conditions.

- Waste Collectors

Waste collectors face health risks from exposure to hazardous waste materials and potential accidents while operating collection vehicles.

The Human Factor: Bravery and Dedication

These high-risk professions require more than just skills and training; they demand extraordinary bravery, dedication, and a sense of duty. The individuals who choose to pursue these careers understand the inherent dangers but remain committed to their roles, driven by a passion for their work and a desire to serve their communities.

Conclusion

High-risk professions play an essential role in society, serving in critical industries despite the dangers they face. Their dedication and courage inspire admiration and gratitude. While these jobs come with inherent risks, they attract individuals with an unwavering sense of responsibility and a commitment to making a difference in the world. As we celebrate their efforts, we must also prioritize their safety and well-being.

FAQs

- Why do people choose high-risk professions?

People choose high-risk professions for various reasons, including a sense of purpose, adventure, financial incentives, and a desire to serve the community.

- How do high-risk professionals mitigate risks?

High-risk professionals undergo rigorous training and adhere to strict safety protocols to mitigate risks. They also rely on teamwork and quick decision-making in critical situations.

- What are some essential qualities for high-risk professions?

Essential qualities for high-risk professions include bravery, physical fitness, mental resilience, quick thinking, and adaptability to unpredictable situations.

- How can society support high-risk professionals?

Society can support high-risk professionals by providing adequate safety training, equipment, and resources. Additionally, recognizing and appreciating their efforts goes a long way in boosting morale.

- What measures can be taken to improve safety in these professions?

Improving safety in high-risk professions requires continuous evaluation and improvement of safety protocols, incorporating advanced technologies, and providing mental health support for professionals dealing with trauma and stress.

-

Protective Gear and Beyond

Advancements in Safety Equipment for Industrial Jobs

Industrial jobs are fraught with various risks, making worker safety a top priority for employers and industries alike. Over the years, the development of protective gear has evolved significantly, aiming to safeguard workers from potential hazards. This article delves into the latest advancements in safety equipment, going beyond traditional Personal Protective Equipment (PPE) to explore innovative solutions that ensure both optimal protection and enhanced productivity.

Traditional Personal Protective Equipment (PPE)

The foundation of industrial safety gear lies in conventional PPE, which includes helmets, gloves, goggles, earplugs, and high-visibility vests. While these have been effective in providing basic protection, they do have limitations. Heavy materials and lack of flexibility can lead to discomfort and hinder workers’ movements. Thus, there is a need for advancements that address these challenges and offer a higher level of protection.

10 Essential Traditional Personal Protective Equipment (PPE) for Optimal Safety

While advanced technologies continue to evolve, traditional PPE remains a reliable and time-tested defense against various hazards. In this list, we’ll explore ten essential traditional PPE items that are still widely used today to ensure safety and protection.

1. Safety Helmets:

Also known as hard hats, safety helmets offer crucial head protection in industries like construction, manufacturing, and mining. They shield workers from falling objects, impacts, and potential electrical hazards, reducing the risk of head injuries.

2. Safety Glasses:

Eye protection is paramount in work settings with flying debris, chemicals, or intense light. Safety glasses with impact-resistant lenses shield the eyes from potential hazards and help maintain clear vision, reducing the chances of eye injuries.

3. Earplugs and Earmuffs:

In noisy environments, ear protection is vital to prevent hearing damage or loss. Earplugs and earmuffs reduce exposure to high noise levels, safeguarding workers’ hearing health in industries such as construction, manufacturing, and aviation.

4. Respirators:

Respiratory protection is essential in environments with airborne particles, harmful gases, or infectious agents. Respirators provide a barrier to inhalation hazards, protecting the lungs from potentially dangerous substances.

5. Protective Gloves:

Protective gloves come in various materials and designs to suit specific tasks. They shield the hands from cuts, abrasions, chemicals, and biological hazards, ensuring hand safety in occupations such as healthcare, construction, and manufacturing.

6. High-Visibility Clothing:

Workers in low-light conditions or near moving vehicles require high-visibility clothing. These brightly colored garments with reflective strips enhance visibility, reducing the risk of accidents in construction zones, roadwork, and traffic control.

7. Safety Footwear:

Safety shoes or boots provide foot protection against heavy objects, sharp materials, and slippery surfaces. Commonly used in construction, warehousing, and industrial settings, they safeguard the feet from potential injuries.

8. Welding Shields and Goggles:

Welding and cutting processes release intense light and harmful UV radiation. Welding shields and goggles shield the eyes and face from these hazards, preventing arc eye and other welding-related injuries.

9. Aprons and Protective Clothing:

Chemical spills, splash hazards, and biological agents call for specialized protective clothing. Aprons, coveralls, and chemical-resistant garments create a barrier between the wearer’s body and hazardous substances, ensuring full-body protection.

10. Safety Harnesses and Fall Arrest Systems:

For workers at height, safety harnesses and fall arrest systems are vital PPE. These devices prevent falls and minimize the risk of severe injuries in construction, window cleaning, and other elevated work environments.

Remember, using appropriate traditional PPE is crucial for ensuring personal safety and reducing workplace accidents. Always follow the manufacturer’s guidelines and receive proper training to maximize the effectiveness of these essential protective items. Stay safe and protected!

Digital Solutions for Safety Enhancement

The digital revolution has also impacted industrial safety, with Internet of Things (IoT) devices and wearable technology taking center stage. These devices can monitor workers’ health, location, and environmental conditions, providing valuable data for safety analysis. Proactive interventions based on real-time data analysis help identify patterns and predict potential safety hazards, allowing for timely preventive measures. Additionally, Artificial Intelligence (AI) is leveraged to perform automated risk assessments and generate safety protocols based on the data gathered, further enhancing safety standards.

Advancements in safety equipment for industrial jobs have come a long way, transforming traditional PPE into smart and innovative solutions. From intelligent helmets and AR goggles to IoT devices and AI-powered systems, technology has revolutionized worker protection. These advancements not only ensure workers’ safety but also enhance their efficiency and productivity. As industries continue to invest in research and development, the future promises even more innovative safety solutions, solidifying the commitment to keeping workers safe in the workplace.